Maximizing the productivity and energy performance of modern industrial facilities requires specialized expertise in the engineering of high-efficiency steam and condensate systems. At TEL, we specialize in the engineering of high-efficiency steam and condensate systems, a critical component for the productivity and energy performance of modern industrial facilities. Our holistic approach ensures that every aspect of your steam system, from generation to recovery, is optimized for maximum reliability, safety, and energy conservation. We design solutions that not only meet your process demands but also significantly reduce operational costs and environmental impact.

Integrated Design for Peak Performance

An efficient steam system is more than just a boiler; it is an integrated network where every component works in harmony. Our engineering services cover the entire system lifecycle to deliver a balanced and highly efficient solution that prevents energy waste and enhances plant output.

Our Comprehensive Engineering Services

We provide a full spectrum of services to ensure your steam and condensate system is meticulously planned, designed, and managed. Our core areas of expertise include:

- Steam Demand Analysis: We begin by conducting a thorough analysis of your facility's process requirements to accurately determine the steam demand, ensuring the system is perfectly sized for your needs.

- Steam Generator (Boiler) Selection: Leveraging our technical expertise, we assist in selecting the most appropriate and efficient steam generator to serve as the heart of your system.

- Boiler Fuel Calculation and Selection: We perform detailed calculations to identify the most cost-effective and environmentally responsible fuel source for your boiler operations.

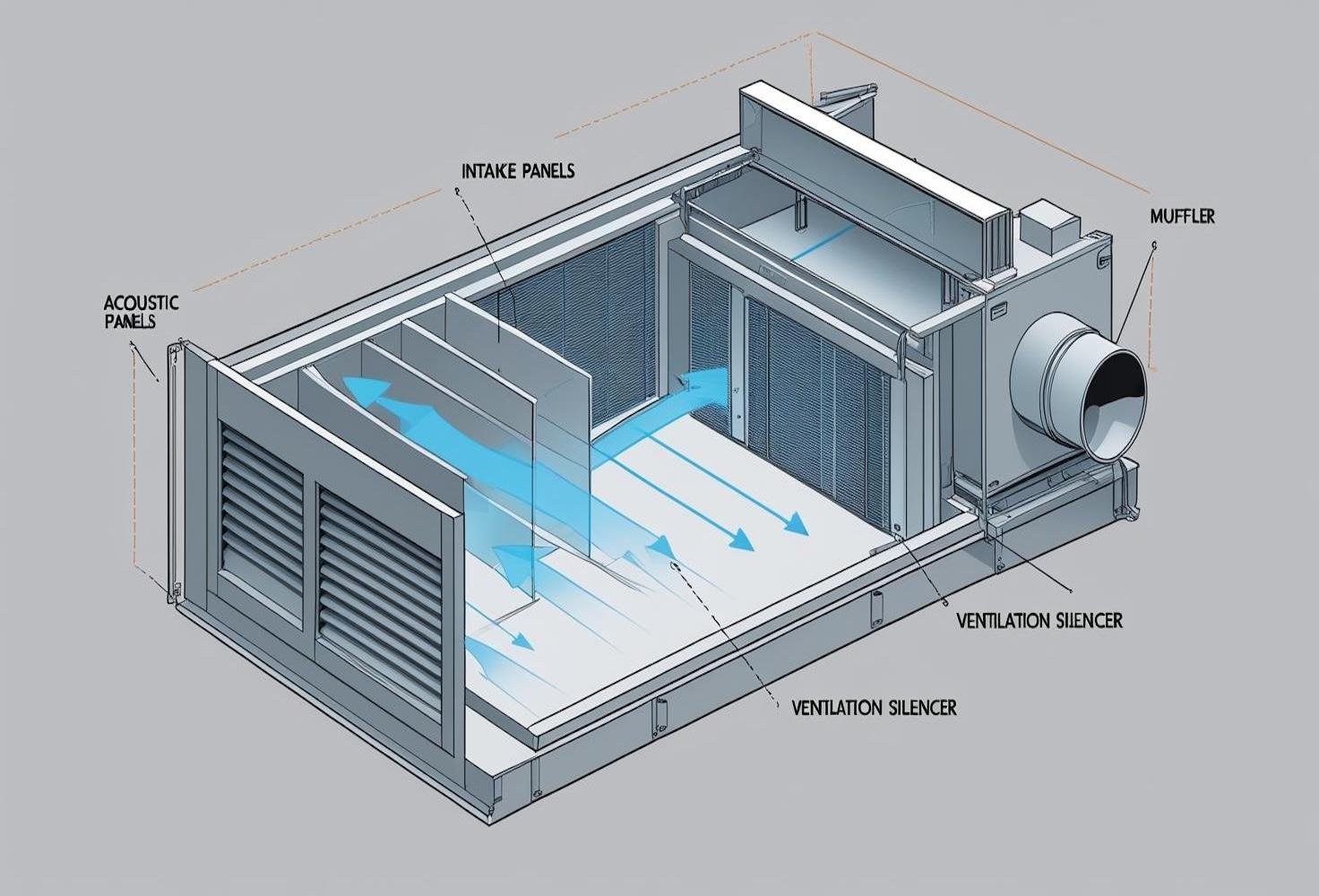

- Boiler Room Layout and Ventilation: Our designs prioritize safety and compliance, creating optimized boiler room layouts with adequate ventilation to ensure safe operation and maintenance access.

- Steam Supply and Distribution Network: We engineer robust piping networks to distribute steam efficiently, minimizing pressure drops and heat loss from the boiler to the point of use.

- Piping and Control Mechanism: We design and implement advanced control mechanisms and valves to ensure precise temperature and pressure regulation throughout the network.

- Thermal Stress and Piping Loop Design: To ensure system longevity and safety, we perform detailed thermal stress analysis on piping and incorporate properly engineered expansion loops.

- Thermal Insulation Design: We provide expert insulation design and selection to minimize thermal energy loss, a critical factor in maintaining system efficiency and reducing fuel costs.

- Condensate Management and Heat Recovery: A key focus of our service is designing effective condensate return systems and integrating heat recovery technology to capture and reuse waste heat, dramatically improving the overall thermal cycle efficiency.

At Triangle Engineers Ltd. our services include:

The TEL Advantage: Efficiency, Safety, and Sustainability

Partnering with TEL for your steam and condensate management needs translates into tangible benefits for your facility. Our expert engineering leads to reduced fuel consumption, lower operational costs, enhanced system safety, and a minimized carbon footprint. Let us empower your operations with a world-class steam system designed for the future.

Powered by engineers

Our Services:

Powered by engineers

News & Blog:

27/11/2025